SPZ-B M.F induction heater with transformer

SPZ-B M.F induction heater (with transformer)more >

SPZ-B2-II MF heater with mini headmore >

SPZ-B M.F induction heater with transformerintroduction

Generally to say, We do not have whole set of SPZ-B machines in stock, we have stock of only SPZ generator, whereas the capacitor and MF transformer will be designed and manufactured as per the work pieces and heating requirement of customers.

We need below information from customer for consultation and purchase:

(1) Material and dimension of the work piece to be heated,

(2) Heating application and speed, heating time required; total piece heating or only surface heating ? If surface heating, how much thickness? Etc.

(3) Any restriction on the shape and size of the coil? If it is heating from inside or outside? If the coil is enclosed or C-shaped? Is there any metal material easily induction heated within 100 mmfrom the coil?

(4) Any requirement for the frequency?

(5) Heating environment: in open air or vacuum? Is there any protection gas?

(6) Any other detail in relation to the machine design?

Structure 1: Generator + Capacitor + Coil (or Induction Furnace)

The structure is without MF transformer, as indicated below:

Above structure is very popular in MF induction heating machines, Such as MF rod heating machines, MF Melting Furnaces, and so on. It is simple, low power loss, higher efficiency, and low production cost. On the other hand, this structure has its limits and disadvantages.

Limits and disadvantages for the MF Induction Machine without transformer:

(1) Without transformer, the coil should be long or big size which is usually made with 5 to 15 meters long copper tube to get enough big inductance of the coil to get working frequency lower than 20KHZ.

(2) Since the coil is directly connected from the MF generator without transformer, so coil is not isolated from the main power circuit and the maximum voltage between the coil can be 550 volt high, this will cause danger to operator. So the coil and connections must be full insulated to avoid touching by the operator when working.

(3) 550V voltage on the coil will cause sparks in vacuum.

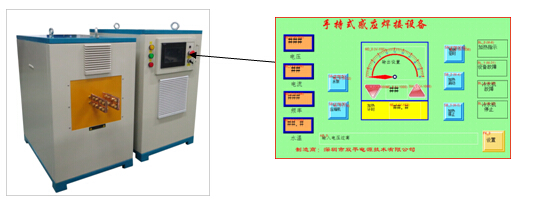

Structure 2: Generator + Capacitor + MF Transformer + coil (or induction furnace)

This structure is with MF transformer, as indicated below:

or:

This structure is widely used also, such as vacuum melting furnace, MF Quenching machines, single rod heating, big parts brazing and so on. The advantage is as below:

(1) By changing the ratio of the transformer to get different output voltage and frequency on the coil to suit different applications.

(2) By changing the ratio of the transformer, the induction coil can be made with less turns( 1 to 10 turns for example), of small inductance.

(3) Since the coil is isolated from the main power circuit, the coil is safe from electric shock, the coil can be low insulation, or even exposed without insulation.

(4) With the transformer, the coil voltage can be lower than 300 volts to avoid sparks in vacuum.

(5) Due to the adding of the MF transformer, the system cost is higher, and the size is bigger. The transformer increases a little energy consumption. The lower the frequency, the bigger the size of the transformer is, the higher the cost, and more the power loss.

Take Model SPZ-45B 45KW machine as example :

1、 Single Cabinet Machine

SPZ-B series heating machines with transformer supplied by Shuangping are mostly dual cabinet, as showed in above t. Single cabinet machine can be made as required by customer. Refer to the picture below:

The advantage of the single cabinet is space saving, easy installation and without problem caused by connection cable.

2、Control panels

(1) Normal SPZ front panel:

Since most of MF induction heating is long time or continuous working, normal front panel is installed on the machine, as indicated below pictures. With only start and stop button, and power adjust knob, it is easy to operate.

(2) Front Panel with timer:

As Picture below, apart from Start, Stop buttons, Timing function is added, the power and time of the two heating process are adjustable.

When purchasing, if you put “A” on the Model, it means to the front panel with timer, for example, Model SPZ-45AB is with timer function.

(3) Front Panel of current/voltage/frequency/power four display

For standard SPZ-B front panel, there is only one display meter, to indicate the value of voltage or power, by putting the relative button to read the value of frequency or current.

Refer to the picture below, two types of front panel is available to order to display four parameters at same time. Front panel on the left is with additional heating timer function.

(4) Touch Screen operation panel

As indicated below, it is available for all models. With PLC control and touch screen operation panel, it offers multi operational interface, with function of pre-set and storage of process data.

3. Two or multi heating output

As picture below, one generator supply the power for two output units and two coils. We can supply two working modes for such structure:

(1) Two coils can not work at same time.

Used for most of cases, the two output units and coils can be different, for heating different work pieces. There will be a converter to switch the generator to one of the two output unit to heat, at the same time, another output unit is not connected.

(2) Two coils heat at same time:

The two output units and coils heat together, but there is limits, the two output units, two coils, and parts to be heated should be same or similar when using this structure.

The electrical diagram of SPZ-B with capacitor on secondary side is as below:

The advantages of this structure is the lower power loss of the transformer, so it is energy saving. Refer to above diagram, taking Model SPZ-45B/45KW as example to explain the energy saving principle of the transformer. primary side current is 90A, secondary side current = ratio * primary current =90A~360A . Coil current is usually 1000~2000A related to capacity and the load. The primary and secondary side current of transformer are low to have less power consumption.

As comparison, in regular quenching transformer, capacitor is paralleled on the primary side of the MF transformer, as indicated in the diagram below.

Also take model SPZ-45BP as example, if the current on the coil is 2000A, the current on the secondary coil of transformer equals to the coil current. Current of the primary coil I primary is500A(if the ratio is 4), therefore current on both primary coil and secondary coil is high, resulting high power loss and consumption.

Below are two kinds of capacitors commonly used: regular oil immersed capacitor and new film capacitor (small cap).

When small capacitors are used, the dimension and weight of the output unit or the capacitor box decreased. If small capacitor is used in the heating machine of SPZ-B2-II series, the capacitors and the coil can be installed together, without the water cooled cable. This way the power loss is decreased a lot, and the machine heating efficiency is higher. As shown by below figures:

By contrast, regular machine is connected this way:

Since the capacitor box is big, usually water cooled cable is used for the connection to the coil, the cable is 1 to 2 meters long, or even longer. The current through the water cooled cable is same as current on the coil, usually as high as 1000~5000A. The higher power the machine is, the higher the current through the coil. So you can imagine how big the power loss is on the water cooled cable. This problem is solved by using small capacitors, and heating efficiency is raised a lot, the machine is power saving.

Location:

Location:

Medium frequency induction heating machine

Medium frequency induction heating machine

Company address

Company address